How to Turn Your Maintenance Team into a Profit Center

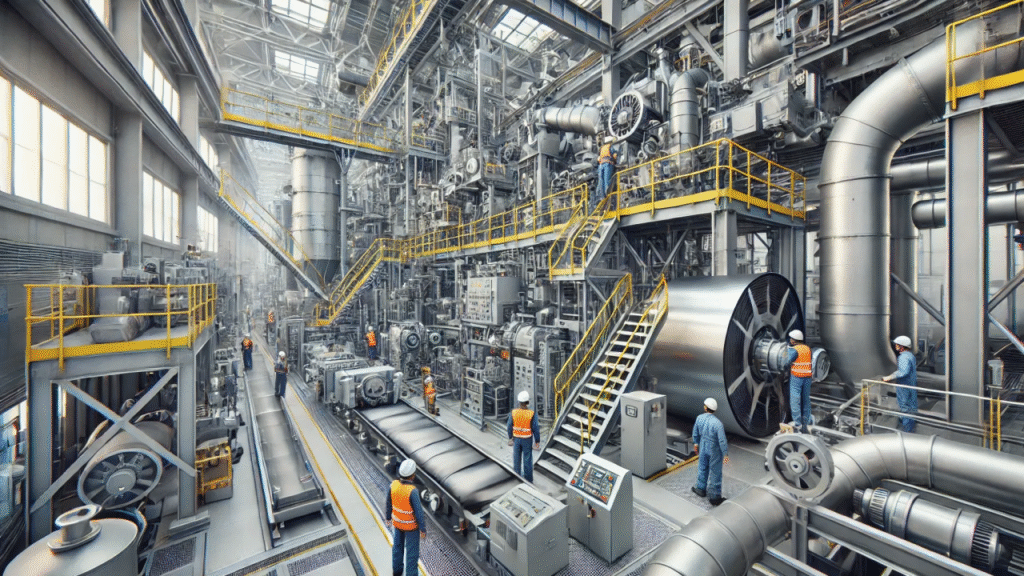

Maintenance is often seen as an unavoidable expense—a cost center that consumes budget but doesn’t directly impact profitability. But by shifting your focus to reliability, you can transform maintenance into a profit center, cutting costs and driving operational efficiency. Here’s how AMSS Consulting can guide you in making your maintenance efforts pay off.

Understanding the Difference Between Maintenance and Reliability

Maintenance typically focuses on fixing equipment after it breaks down. This reactive approach keeps things running, but it doesn’t add value. Reliability, on the other hand, aims to prevent equipment failure, reducing the frequency and cost of repairs. By optimizing maintenance processes and predicting potential issues, reliability ensures that equipment operates at peak efficiency, which ultimately impacts the bottom line.

“Maintenance is a cost center because it always costs money to repair and maintain equipment. Reliability is a profit center because it minimizes these costs and maximizes uptime.” – Brian Brzinski, Founder of AMSS Consulting

Key Strategies for Optimizing Your Maintenance Process

Shifting your maintenance approach from reactive to proactive can significantly reduce costs and improve reliability. Here are a few ways to achieve that:

Predictive Maintenance (PdM) uses data to anticipate equipment failure before it happens. By using sensors, IoT devices, and artificial intelligence, you can monitor equipment in real time, allowing you to address potential issues before they lead to downtime. This approach ensures maintenance occurs only when necessary, extending the life of equipment and reducing unexpected breakdowns.

Preventative Maintenance (PM) programs are essential but can often miss the mark if they don’t align with the real needs of your equipment. By regularly reviewing and refining your PM programs, you can ensure they address the most common failure modes and prevent unnecessary repairs. This proactive approach helps keep equipment running smoothly without wasting time on unneeded maintenance.

Condition-Based Maintenance (CBM) is another proactive method, where maintenance is only performed when specific conditions indicate that equipment performance is declining. This approach allows you to intervene at the right moment, ensuring maintenance is performed only when necessary, saving costs and resources.

The Value of Reliability in Your Business

Emphasizing reliability can deliver substantial benefits, both in cost savings and operational performance.

- Maintenance costs decrease significantly as you reduce the number of reactive repairs and emergency fixes.

- Equipment life is extended, reducing the need for capital investment in new machinery.

- Downtime is minimized, which leads to improved productivity and a smoother production process.

- Forecasting becomes more accurate, allowing you to better plan for future maintenance needs and control budgets.

How AMSS Consulting Can Help

At AMSS Consulting, we specialize in helping businesses optimize their maintenance processes for improved reliability. Our team will assess your current systems and provide actionable insights on how to shift from reactive to proactive maintenance. Whether it’s implementing predictive and condition-based strategies, or refining your preventative maintenance, we ensure your plant operates at peak efficiency.

Move From Cost Center to Profit Center

Shifting to a reliability-driven maintenance strategy can transform your operations, reducing downtime, extending equipment life, and improving cost efficiency. It’s time to turn your maintenance department into a profit center by focusing on reliability.

Want to see how reliability can work for you? Contact AMSS Consulting for a free consultation and start optimizing your maintenance strategy today.