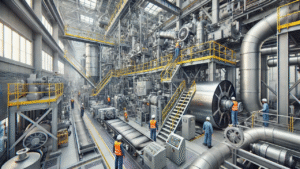

The Real Reason Your Maintenance Schedule Keeps Slipping

If your maintenance planning meetings feel like a waste of time—or worse, if they’re not happening at all—you’re probably stuck in a reactive cycle that’s hurting productivity and reliability.

The good news? A great planning meeting doesn’t have to take long. In fact, 30 minutes a week can change the way your team executes maintenance.

Here’s what that looks like in practice:

1. Start with the Right People

Keep it lean, but cross-functional:

- The planner who owns the schedule

- The supervisor who knows the crew

- An operations rep who understands production windows

- Optional: someone who can speak to parts or reliability

2. Follow a Simple Structure

Your weekly planning meeting should:

- Review what was planned vs. completed last week

- Surface any deferred work and why it’s waiting

- Walk through the schedule for this week—confirming labor, parts, and access

- Flag any high-risk jobs or potential conflicts

- Adjust and lock the plan before Monday starts

3. Stay Focused on Execution

This is not the time for strategy, design reviews, or long debates. Keep it moving. Use a visual schedule or dashboard. End with clear ownership and expectations.

4. Why It Matters

A good meeting avoids surprises. It keeps priorities clear, reduces last-minute changes, and helps you stay ahead of backlog.

If you’re holding meetings but still missing the mark—or if you’re not holding them at all—it’s likely the structure that needs work, not the people.

Want help building a better execution rhythm?

Reply to this email and we’ll schedule a time to walk through what’s working, what’s not, and where we can help.

- « Previous

- 1

- 2

- 3