Stop Wasting Money on Unnecessary Maintenance—Here’s How

Preventative maintenance is supposed to save money and prevent failures, but if it’s not aligned with real equipment needs, it can do the opposite—driving up labor costs, wasting parts, and still not preventing breakdowns.

Is your PM plan actually saving you money?

Here’s how to make sure:

1. Use Data, Not Guesswork

Base PM schedules on failure history, equipment usage, and real-world performance—not just OEM recommendations.

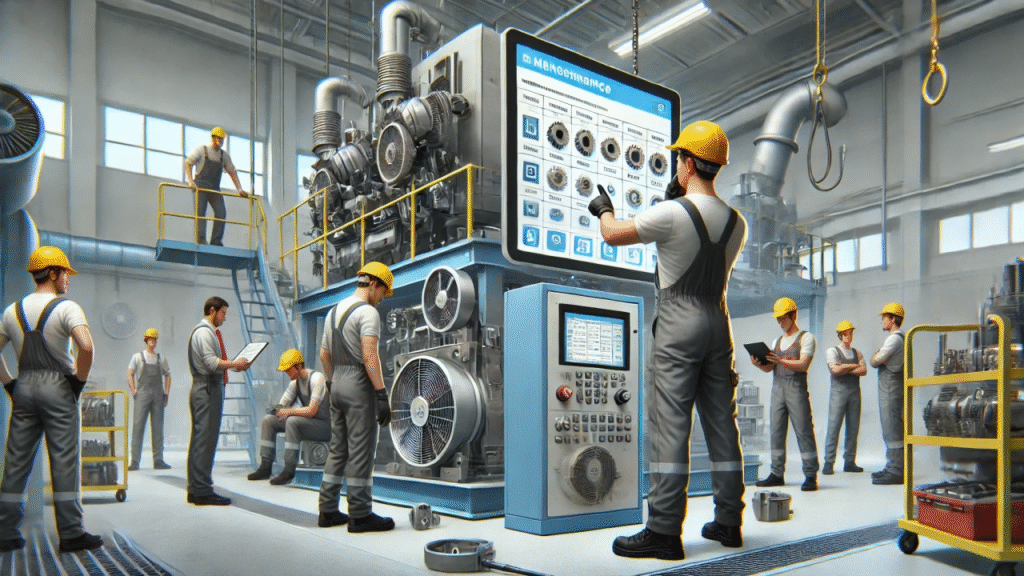

2. Avoid Over-Maintaining Low-Risk Equipment

Servicing some assets too frequently can drive up costs without improving reliability.

3. Integrate Condition-Based Monitoring

Track vibration, temperature, and other indicators to perform maintenance only when necessary.

4. Fine-Tune Your Schedule

Adjust PM intervals based on data to reduce unnecessary work while keeping equipment in peak condition.

A well-structured PM plan should cut costs, reduce downtime, and extend equipment life—not drain resources.

Want help optimizing your preventative maintenance strategy?

Let’s schedule a quick call to review your current approach.

Reply to this email, and let’s make sure your PM plan is working for you.