How to Align Maintenance and Operations for Better Reliability

When maintenance and operations aren’t on the same page, reliability suffers. Misaligned schedules, unexpected downtime, and last-minute repairs create unnecessary costs and delays.

Here’s how to bridge the gap and improve collaboration.

The Cost of Poor Coordination

- Unplanned Downtime – Production schedules get disrupted by unexpected repairs.

- Inefficient Maintenance – Work orders clash with production demands, leading to delays.

- Equipment Failures – Lack of shared data means early warning signs get missed.

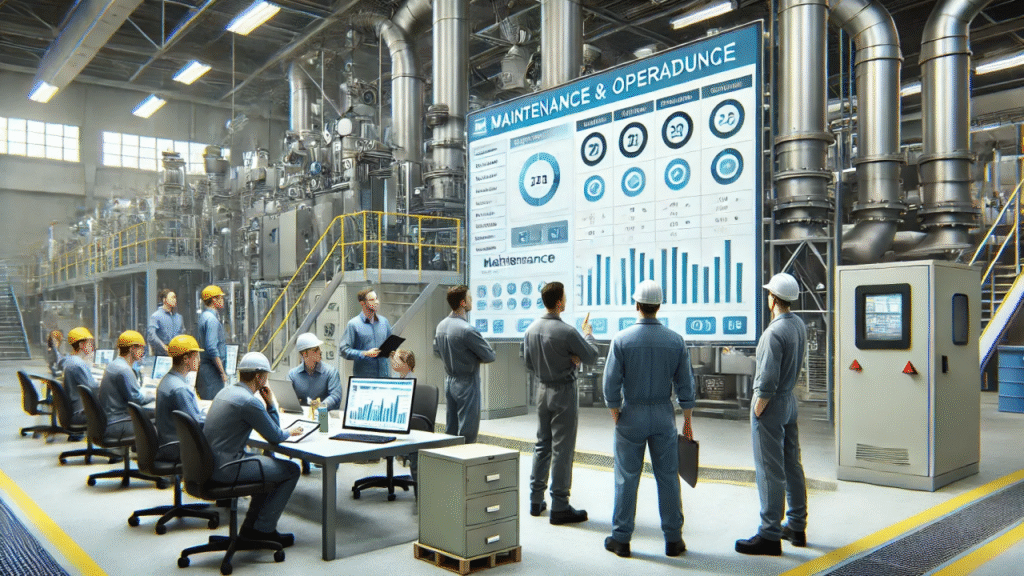

How to Improve Maintenance & Operations Alignment

- Schedule Together – Align maintenance tasks with production cycles to minimize disruption.

- Improve Communication – Regular check-ins ensure both teams are aware of upcoming work.

- Use Shared Data – A CMMS helps operations and maintenance teams track asset health and plan smarter.

The Bottom Line

Better coordination means fewer breakdowns, reduced downtime, and improved efficiency. If your teams are operating in silos, it’s time to fix it.

Need help aligning maintenance with production? Contact AMSS Consulting today for a strategy that works.

- « Previous

- 1

- 2

- 3

- Next »